|

|

Details technology determines the success or failure of the product: 0.X moment of small-pitch LEDAs one of the most important exhibitions in the LED display industry throughout the year, Shenzhen LED China 2020 and ISLE exhibitions ended on September 3. However, the thinking that LED China 2020 brings to the LED industry is not over. In particular, the large-scale implementation of P0.X products and the rapid pace of the "race" of scene innovation and process innovation under new technologies are impressive.

Smaller spacing, closer audio-visual distance, finer process indicators "What is the leveling rate requirement? It turned out to be a percentage, but now it is 100%!" An industry insider commented on his newly launched p0.9 pitch LED TV products. ——This is an important reason why "integrated products" rather than "spliced" products are used for this type of 100-inch upper and lower applications: only a fully factory-based standard process can ensure a high level of leveling effect. Industry insiders said that the history of the development of LED display large screens is not only "the spacing index is getting smaller and smaller", but also "the viewing distance is getting smaller and smaller." For example, many outdoor large screens require a viewing distance of 100 meters, while indoor large screens and command and control centers require a viewing distance of 5-10 meters. Now, entering the P0.X era, in the 8K scene, the viewing distance of the product is compressed to 3 meters or even smaller.

This change in viewing distance and conditions has brought about a systematic upgrade of the product "parameter fineness" (not just the spacing index). For example, a large screen under outdoor sunlight, a point distance of centimeter level, and a 0.5 mm difference in leveling may not significantly affect the visual effect. However, the P0.5 product has a 0.1 mm difference in flatness, and the visual difference is obvious. For another example, the outdoor large screen, thousands of lumens of super bright experience, to achieve a real visual contrast of 100:1, a contrast level may be a gap of tens of lumens; while many indoor screens, although the peak brightness is still 1000-2000 Lumens, but the normal average brightness (such as a 100-inch product) is only five or six hundred lumens, achieving a 100:1 visual actual contrast difference, and the difference in one gear is only a few lumens...

Similar changes are numerous! It can be said that the P0.X era brings the entire small-pitch LED display product, and the "precision" of the whole system is improved: contrast, brightness, color control, black consistency, flatness, reliability, and stability have reached the previous products. Ten times, dozens of times! Even the chip processing volume per unit time can reach more than a hundred times that of the original product.

Because of this, at the LED China 2020 exhibition, ultra-thin products are already the highlight technology, light-weight cabinets have been widely popularized, COB technology is not enough, flip-chip COB, massive transfer COB successive upgrades-from packaging to terminal, to Detection and repair, the small-pitch LED industry is undergoing a battle of "process precision".

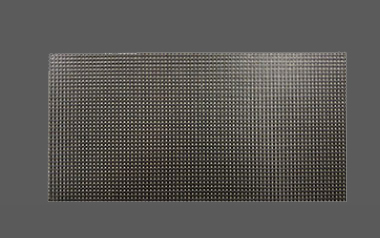

Efficiency comes first, and a huge amount of transfer becomes the key to P0.X Displays with a pixel pitch below P1 need to put more and denser three-primary-color (RGB) lamp beads. A 1920*1080 screen requires more than six million lamp beads. However, this screen area is only one to two square meters. How to realize the manufacturing of such products in the P0.X era! Mass transfer technology is the key. That is, LED large-screen companies no longer buy "made lamp beads and then solder them on the circuit board", but "purchase LED wafer products directly, and use massive transfer technology to package the chips on the circuit board": less An intermediary-packaging companies, LED large-screen terminal manufacturers have more technical discourse power, of course, it also brings the increase in the difficulty of innovation.

?What's more, under the huge demand for the transfer of massive LED crystal particles on a display wall, "production efficiency" is the mother of cost. And cost is the key to marketing and competition. Competing over who runs faster and with higher accuracy in mass transfers has become the core competitiveness of the industry in the P0.X era. This also makes many large LED screen companies become "chip-level" manufacturers. "Traditional P&P equipment processing speed is about 110,000 points/hour, our mass transfer technology is 2.5 million points per hour! And achieve 100% accuracy", AET interpreted the "efficiency" change of mass transfer technology in this way.

"From direct insertion to surface mount, to four-in-one lamp beads, and then to mass transfer, the threshold for LED display large-screen technology is getting higher and higher." According to industry sources, it is only the cleanliness of the space required by the mass transfer process. Can eliminate more than half of the small and medium-sized LED screen manufacturers. Mass transfer is where the core competitiveness and technical barriers of the future industry lies, and it is also the core bottleneck that determines the ultimate "limit" scale of the LED small pitch direction. Even, the process, actual accuracy and choice of materials used in the mass transfer technology also determine the final performance of the product in terms of life, color cast, contrast and other indicators: at the LED China 2020 exhibition, any manufacturer that launches samples around P0.5 , All pay attention to massive transfer technology. This technology has become one of the "biggest highlights" of the products of international giants such as Samsung and Sony.

The craft is getting more and more refined, the industry is worried about "external competition" "LED display technology is becoming more and more common in the era of micro technology and mass transfer." Industry insiders pointed out that including VR, wearables, in-vehicles, and TV are all scenarios for new LED display technologies. This creates a problem: LED large-screen companies cannot eat so many new scenarios; it is impossible for existing manufacturers in these scenarios to allow LED large-screen companies to eat all the scenarios.

Therefore, at the LED China 2020 exhibition, the industry's biggest competition concerns about P0.X and even P0.0X products go beyond the traditional LED display industry. For example, in 2019, TCL launched the first actively driven Mini LED product based on a glass substrate-Xingyao Screen Technology. In theory, this technology has a great "technical overlap" with small-pitch LED displays. Foreign media also reported that in 2021, Samsung may launch a new system of LED TV products with "mini-led+QD filter film".

At least from a technical point of view, for traditional semiconductor panel companies, micro-led and massive transfers will not be much of a problem. In addition, panel companies have the advantage of glass substrates. If ultra-fine LED displays use glass substrates as drive carriers in the future, panel companies will have inherent advantages. Even the worry about "external competition" extends to the market. At the LED China 2020 exhibition, Hikvision, Dahua, Huawei, and the top three domestic (and global) largest security industries have all entered. These companies "overlap" the security, smart city, conference room, command and dispatch center market with the traditional small-pitch LED screen corporate market, and these companies have stronger strengths and higher comprehensive capabilities.

Therefore, after LED screen companies at LED China 2020 are thinking about technology "upgrading", new forces such as TV, panel, and smart industry giants may participate in the market in the era of spacing below P0.X, and believe that this is the "biggest competition" facing the industry. Challenges"-As for the competition within the industry, on the contrary, it is the low-risk aspect of "being familiar with the road". "We launch LED TVs, and TV manufacturers will also launch them. Who wins or loses will have to be tested by time!" The expansion of the "competitive plate" and the "new application of P0.X" mean new competition laws and industry rules. This is the industry The biggest risk variable. In summary, with P0.X as the core symbol, small-pitch LEDs have entered a new era of "ultra-fine technology" upgrades and "market dimensions" expansion, which also means changes in industry competitiveness and competition participants. LED China 2020 shows this point vividly and exquisitely. These changes will become major variables that will influence the future pattern of the industry in the long term. |